TURNING

All machining is done with high precision CNC lathes and multitasking.

L.M.P. offers the turning service which is an industrial production process obtained by chip removal. We specialize in the production and processing of turned components on different types of ferrous and non-ferrous materials, hardened materials, alloys and super alloys.

All machining are carried out with high precision CNC lathes and multitasking, managed by our qualified staff, ensuring an excellent quality standard respecting tolerances, finishes and unified machining according to UNI standards required by the drawing.

For the turning operations, the workshop uses the latest technologies starting from the programming and study of mechanical design to the production of the required mechanical components. We also use CAD/CAM software and benefit from our operators' decades of experience.

From a practical point of view, machining is carried out with numerical control machines with automatic bar loading, with robots or, in some cases, with manual loading.

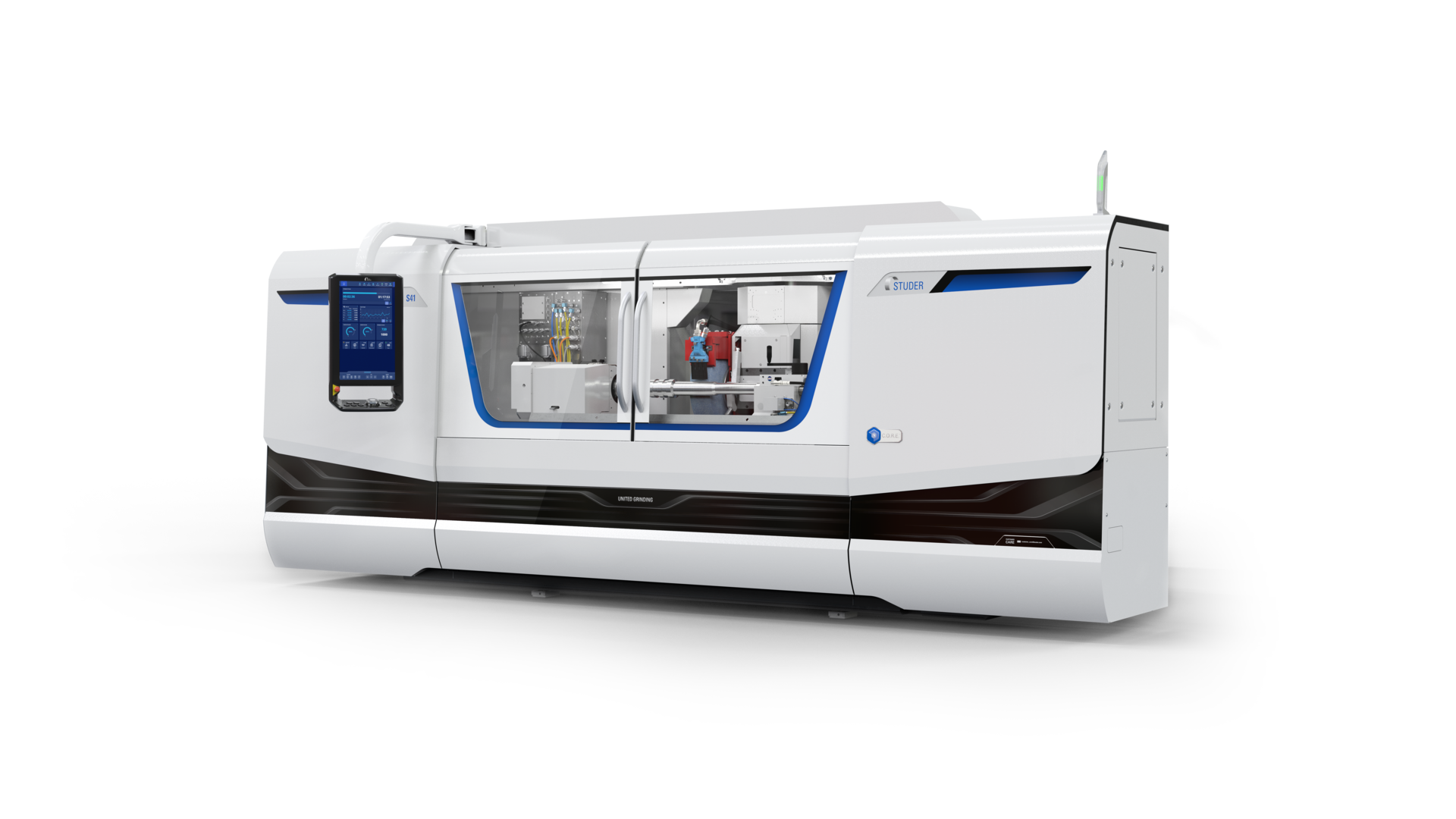

TURNING MACHINES:

- Mazak integrex i-350H turning and milling multitasking center, continuous processing on 5-axis. (5 axis manufacturing in continuous allows the execution of shaped parts for which it is necessary to interpolate the 5 axis at the same time).

- Lathe Doosan CNC double turret with 8-axis, counter spindle and bar feeder ø65

- Lathe Doosan CNC double turret with 8-axis, counter spindle and bar feeder ø80

- Lathe Doosan CNC double turret with 9-axis, counter spindle and bar feeder ø65

- Lathe Daewoo CNC ø 400X1300

- Lathe Daewoo CNC ø 400X600 spindle hole ø 75 mm

- Lathe Daewoo CNC ø 400X600 spindle hole ø 105 mm

- Lathe Daewoo CNC ø 450X600 with C-axis, driven tools

- Lathe Daewoo CNC ø 400X600 with C-axis and Y –axis, driven tools

- Lathe Daewoo CNC ø 400X600 with bar feeder ø max 70 mm

- Lathe Daewoo CNC ø 400X600 with bar feeder ø max 60 mm

- Parallel lathe equipped with deep drilling equipment

- Parallel lathe for equipment

Order management

The use of customized software allows L.M.P. to carry out accurate production planning.

Quality check

Management of batch conformity and traceability at each processing stage with customized software.

ADDRESS

Strada del Collaretto, 27

12030 Caramagna Piemonte (CN) Italia

TELEPHONE

L.M.P. s.r.l. a socio unico

Capitale sociale: euro 500.000,00 i.v.

Registered office:

- Corso Re Umberto, 8, 10121 TORINO (TO)

Operational and Administrative Headquarters:

- Strada del Collaretto, 27, 12030 CARAMAGNA PIEMONTE (CN)

P.IVA/C.F. 11820120019 - Site created by

etinet.it